Project 1:

Autonoumous Window Cleaning Robot

This page describes the work that I have carried out in my final year project for developing an autonomous window cleaning robot capable of contamination detection and position estimation.

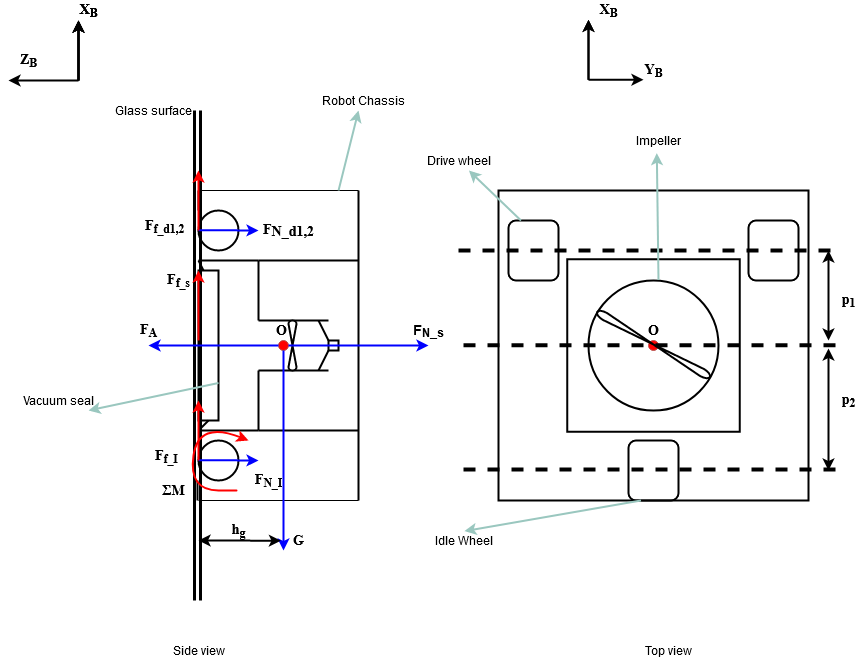

This project tackles the problem of finding a more efficient alternative to costly, labour intensive and risky manual glass window cleaning operations by developing an automatic window cleaning robot. The idea behind this project is to develop a system that solves the aforementioned problem by utilizing an adhesion and locomotion sub-system employing sensors to collect positional and orientation data that will be analysed in a control system in order for the robot window cleaner to traverse the entire vertical glass surface and know where it is on the window.

Find out more and get this Project's GitHub RepositoryThe following video demonstrates the working of the robot.

Motivation

The automation of inspection and maintenance tasks through autonomous robots play a vital role in numerous sectors by not only improving inspection and upkeep quality, but by ensuring a lower health, financial and business risk. These aforementioned sectors that benefit from the automation of inspection and maintenance tasks, to name a few, include the aerospace industry, construction and health care. Even though there is an increasing demand for automation in industrial uses; the growing importance of sustaining a hygienic and clean working or living environment has clearly been emphasised in our current struggle to perform safe daily activities in the on-going world pandemic. The role of automation in inspection and maintenance tasks will not only improve the efficiency at which environments are kept hygienic but will help ensure healthy living environments will be the norm in public spaces in the coming decade. Worldwide there are over 80000 multistory buildings that consists of more than 12 stories; of which more than 30% are glass façades [1]. The glass façades business has a large market, estimated at around 10 billion USD in 2017, with a rapid potential for growth [2,3].

Although the recent improvements in façade construction technologies and processes has resulted in the drastic evolution of building construction; the maintenance and inspection procedures have not. These maintenance operations have remained a dangerous, tedious and labour-intensive process. Numerous cases of accidents have been reported over the last 10 years; one such situation involved a gondola that lost control by a gust of wind at the Shanghai World Financial Centre [4]. Another investigation in Korea revealed that 15 maintenance workers unnecessarily lost their lives during façades-cleaning operations in 2016 [5]. As a safer alternative to maintenance tasks in dangerous environments; a multi-sensor input, positional aware, autonomous window cleaning robot is proposed as a solution.

Business Motivation

According to www.techsciresearch.com, the Global Window Cleaning Robots Market is expected to cross USD 150 Million by 2024, growing at an impressive CAGR of over 15% during the forecast period. The largest share of the robotic window cleaner market is held by North America and is anticipated to be at the forefront of global demand. However, the Asia Pacific market is forecast to be be a strong competitor.

The realizations/designs currently in the window cleaning market consists out of a variety of robots, running from proof of concepts and research projects to full commercial products. Some of the leading players in the Global Window Cleaning Robots market are Ecovacs Robotics Co. Ltd., Hobot Technology, Inc., Zhengzhou Bangmi Smart Technology Co., Ltd., Mamibot, Inc., Windowmate, Cop Rose Robot Co. Ltd., Alfawise, Iishim Global Co., Ltd., Baseltek, ALBOHES.

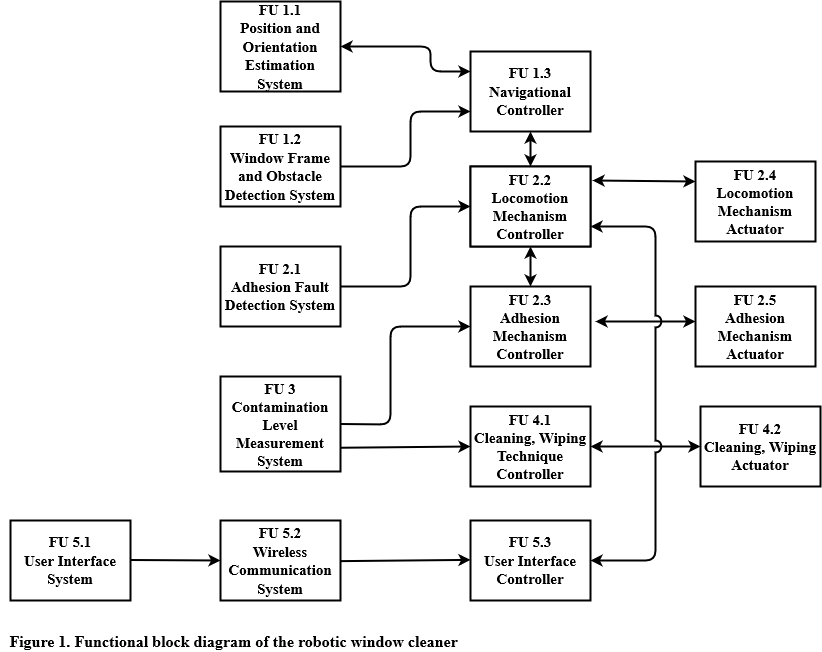

Functional Block Diagram

Functional Discription

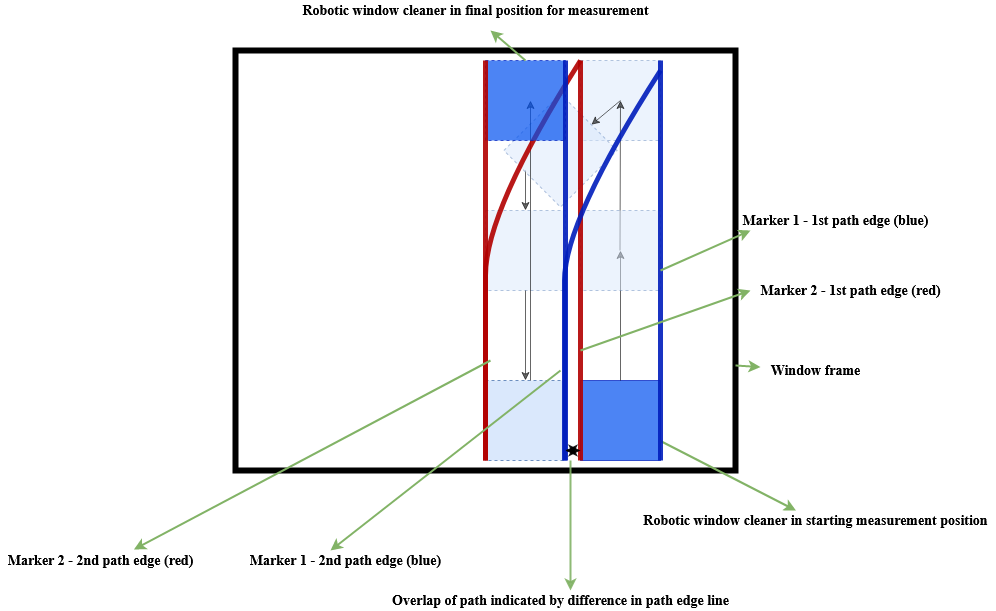

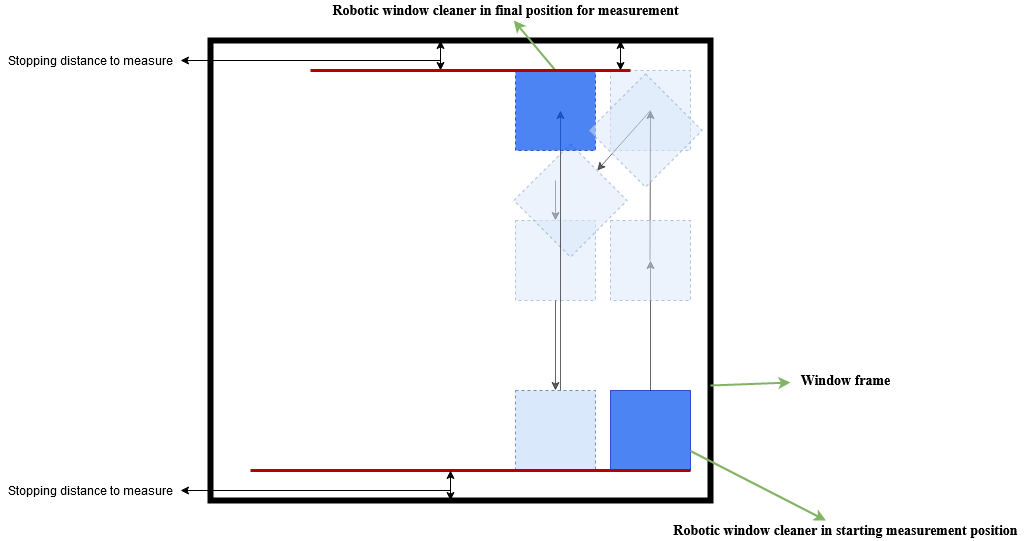

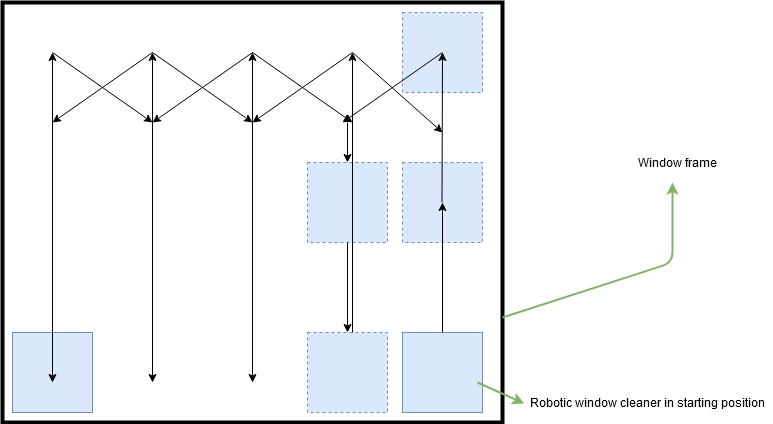

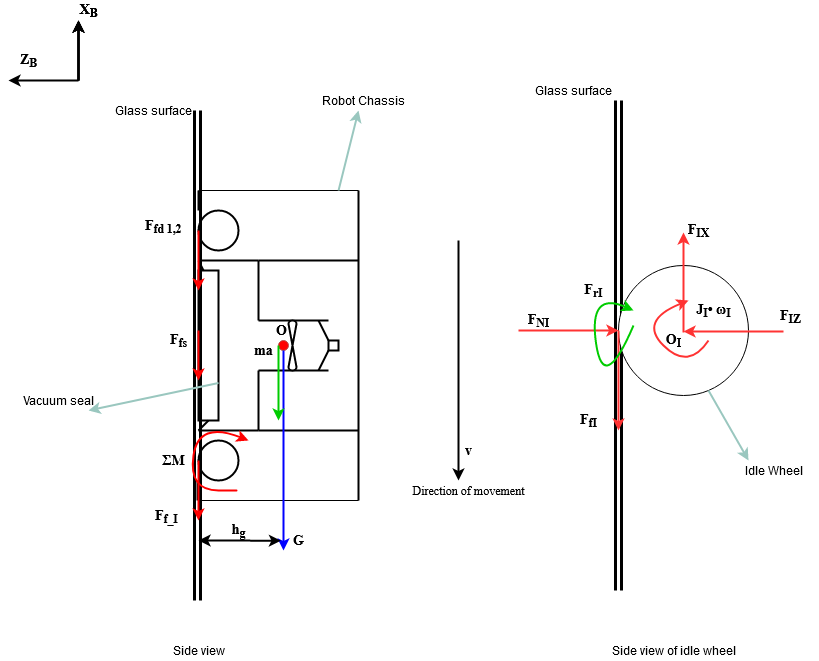

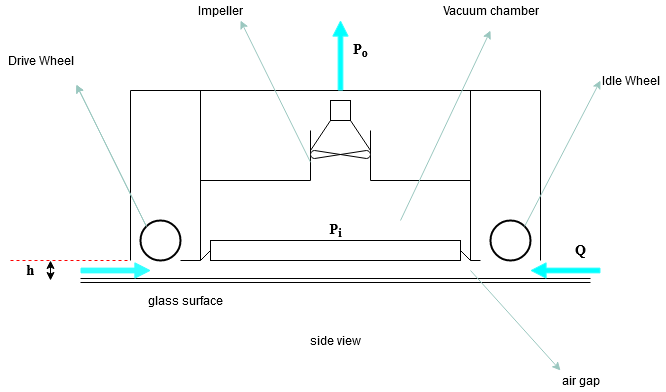

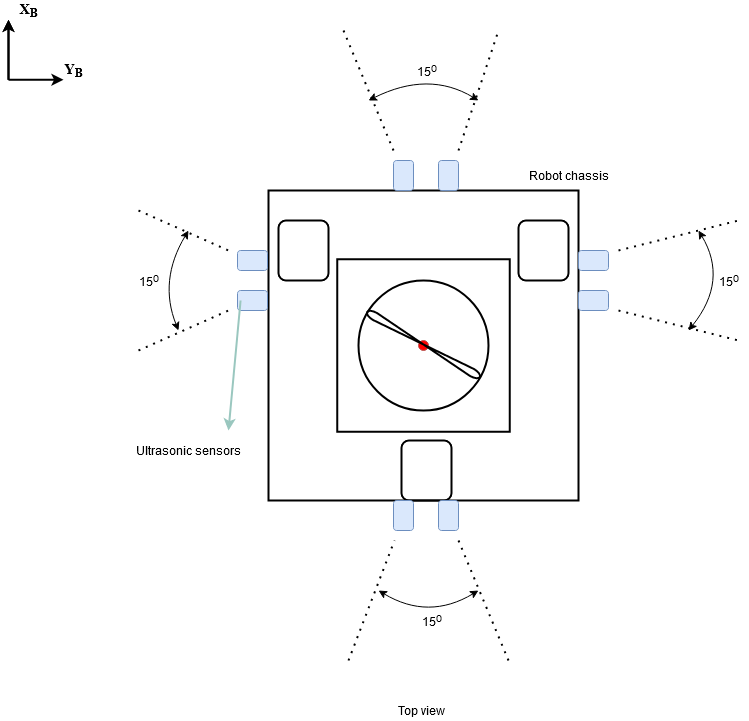

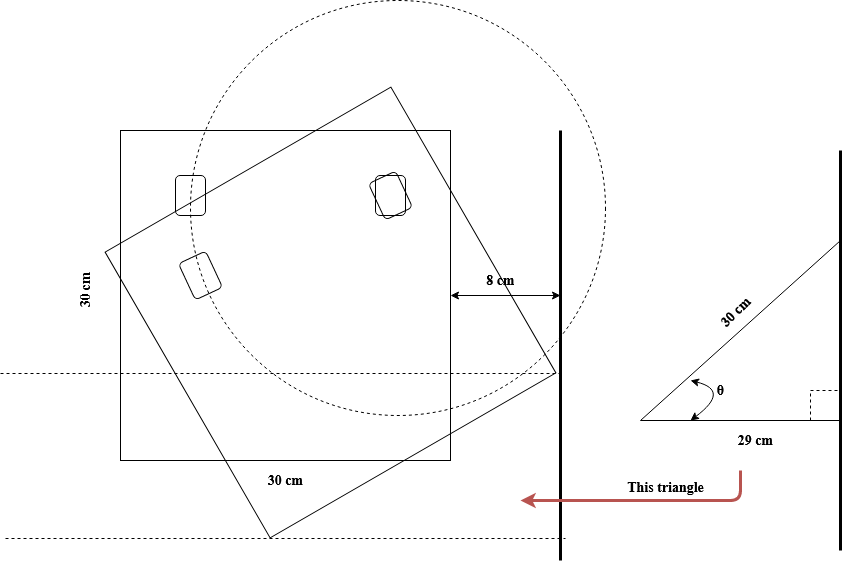

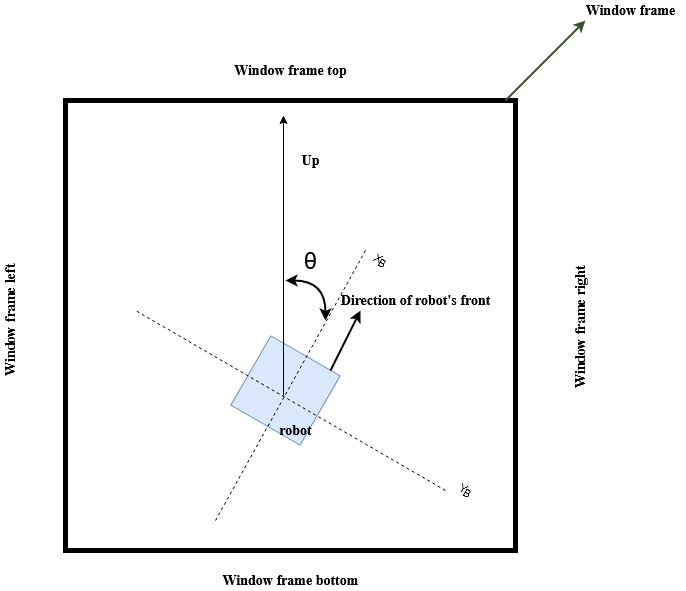

The proposed solution of a window cleaning robot’s functions can be categorized into five main functions as illustrated in the functional block diagram in Fig. 1 above. These functions are the positioning and navigation tracking function (FU 1), the movement and adhesion function (FU 2), filth detection function (FU 3), the cleaning function (FU 4) and the user control function (FU 5). The movement path to ensure all areas of the window are cleaned is achieved with the navigational controller (FU 1.3) which determines a route to clean based on the current position, orientation and the position of the window frame. The function of the position and orientation estimation system (FU 1.1) is to determine the current trajectory and orientation and to relay that information to the navigational controller. The window frame detection system (FU 1.2) identifies the window frame distance and relays the frame position to the navigational controller and the cleaning controller to alter the cleaning time and method. The movement of the robot on the vertical glass is realized with a locomotion controller (FU 2.2) which alters the adhesion strength by sending a signal to the adhesion mechanism controller (FU 2.3) which relays controls to the actuators (FU 2.4-2.5) to maneuver the robot on the glass surface. The adhesion fault detection system (FU 2.1) determines when adhesion strength is lost and informs the navigational controller to stop movement and perform emergency steps to establish suitable adhesion so that the robot does not fall backwards. To ensure the robot spends more time on areas that gather contamination more easily and does not move over an area before it is clean; the contamination level measurement system (FU 3) will determine the filth level at the current position and send this information to the locomotion mechanism controller which will only allow the robot to progress once sufficient filth levels are removed. The cleaning technique controller (FU 4.1) will adjust the cleaning technique. The user interface system (FU 5.1) allows the user to stop and start the robot over a wireless communication system (FU 5.2). The user interface controller (FU 5.3) sends stop/start data to the navigational controller.

The following figures illustrates the designed cleaning path of the robot to cover the entire window as well as the diagrams used for static and dynamic force modelling. A diagram showcasing the window frame detection sensor layout as well as the diagram illustarting orienetation determination is given.

This Project's GitHub Repository